Product Description

1. Function introduction:

1. Function introduction: (1) Precise positioning of pipeline loading and unloading trucks and target positions for assembly work

1) The use of artificial intelligence technology and high-precision equipment to determine the rubber tube trolley, tube storage platform and the position of the tubes to be installed.

2) Create a multi-dimensional characteristic space for the global description of pipeline capture characteristics to achieve the target key capture point, and in combination with specific positional relationship algorithms, through a robot carrying intelligent equipment for pipeline position capture, coordinate data collection and visual image analysis, to complete accurate pipeline position collection.

(2) Multi-sided robot arm with large load and its control

1) Comparison of the relationship between the parameters of the joints and the load of the robotic arm, based on the principle of bionics, construction of a simulation model of the hydraulic system;

2) Perform dynamic analysis of the robotic arm, study the algorithm of planning the trajectory of the robotic arm in the space of well operations, and create data sets of characteristics for different types of operations;

3) Build the dynamic characteristics of joints and management strategy under various disturbances, develop a hybrid management model with deep learning to achieve adaptive smooth management; control the state of movement of the robotic arm using hydraulic servo drives to ensure a high load-to-weight ratio, environmental applicability and smooth operation.

(3) Precise positioning and autonomous operation of the robotic arm

1) Based on accurate target positioning and coordination of the control model through deep learning, the robotic arm can accurately capture and locate the target.

2) With remote control, manual and other manual control demonstrations, reference path travel, automatic learning, analysis and modeling, work model optimization, autonomous operation planning travel.

3) Operational model planning, local deployment and training of algorithms, creation of a diverse library of operational models, application and operation in the field.

4) Autonomous positioning, automatic eye alignment, to achieve accurate setting.

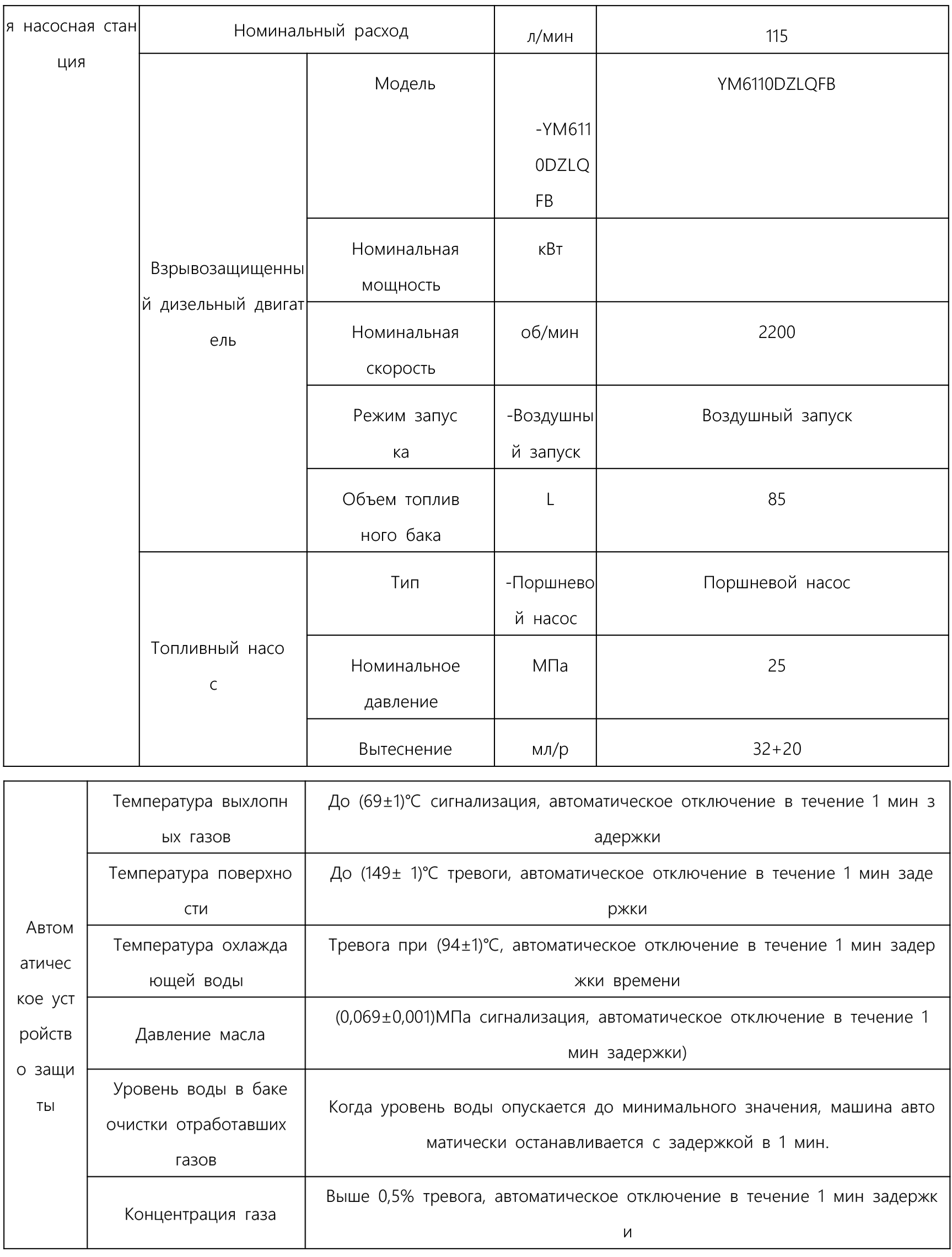

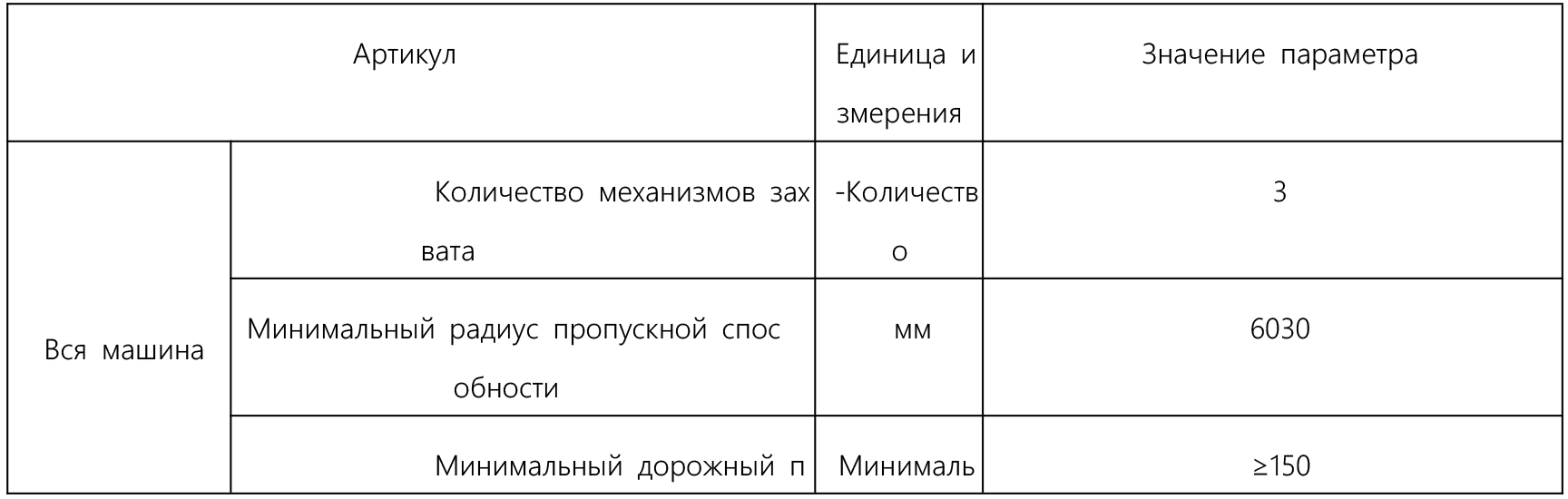

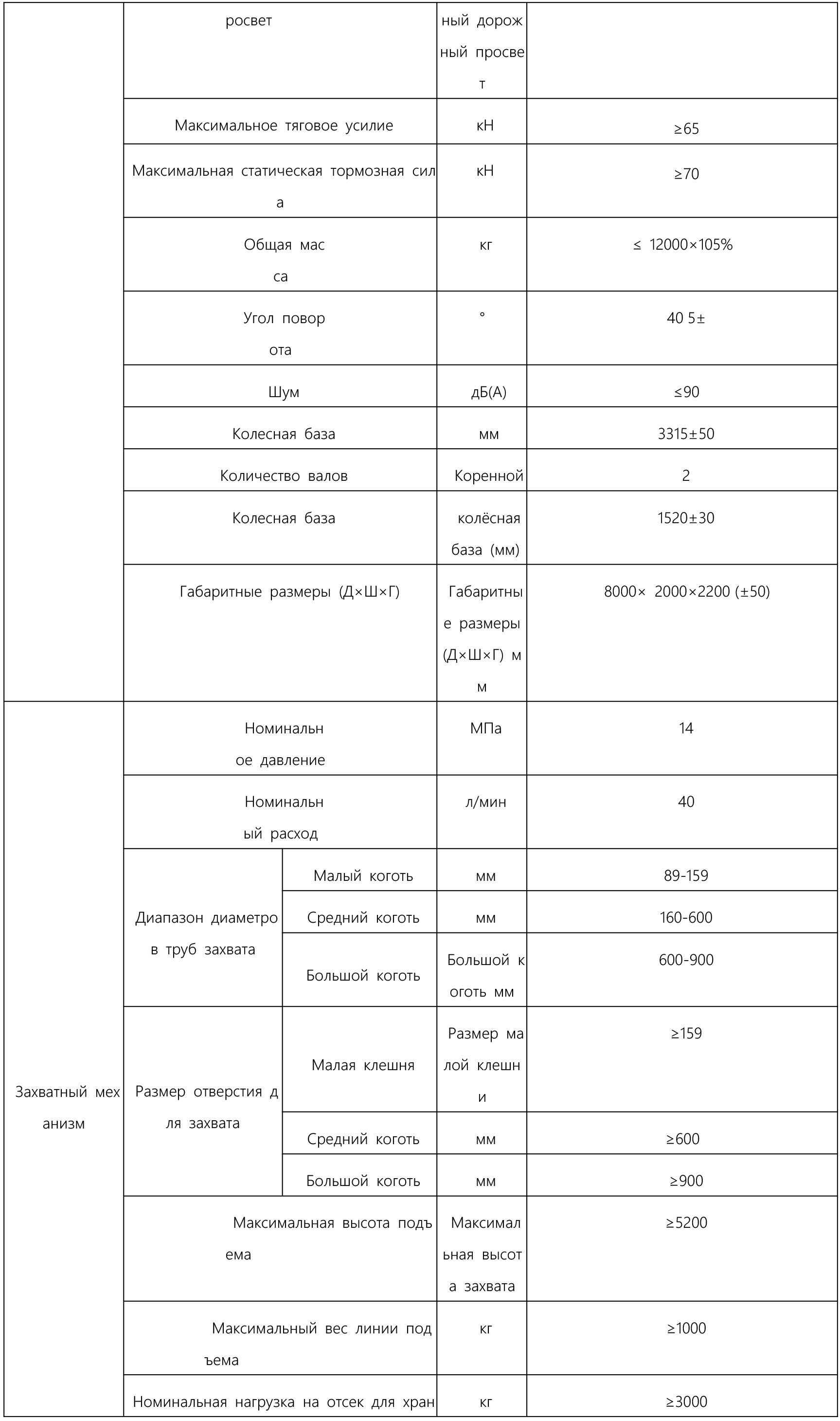

2. Main technical parameters of mining pipe harvesting machine:

2.1, the use of environmental parameters

Ambient temperature: -20℃~+40℃;

Environmental humidity: not more than 95% (+25℃ conditions);

Road conditions: ventilation on the passage at least 300 m³/min.

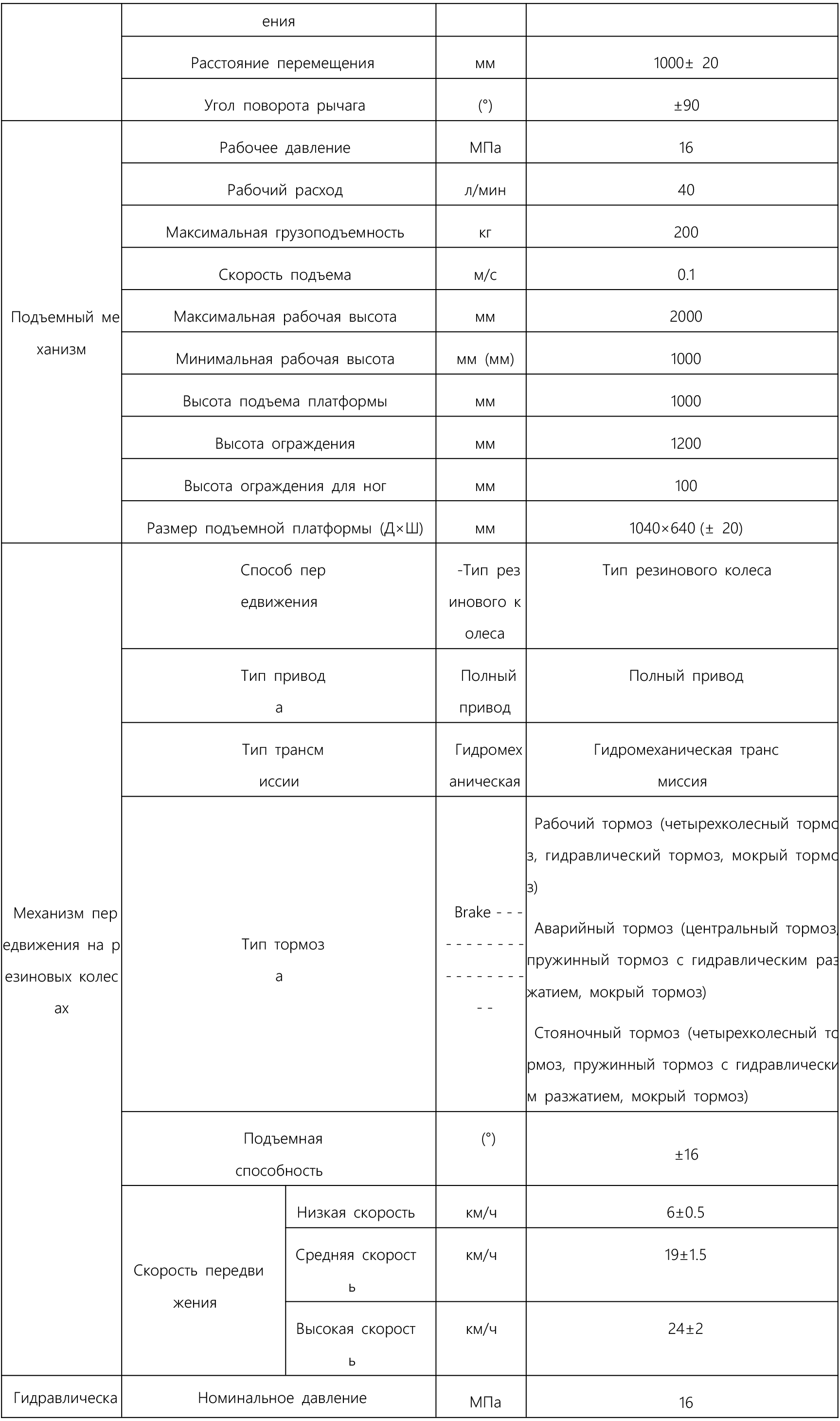

2.2 Main technical parameters

RU

RU CN

CN EN

EN